In many traditional and emerging electrical systems, the idea of a Chuangbiao Low-frequency Transformer Factory remains closely connected with dependable power handling, while the brand name Nbcbdz reflects a structured approach to manufacturing communication and steady collaboration. Together, they frame a conversation that values process clarity, practical design, and thoughtful coordination rather than short-lived trends.

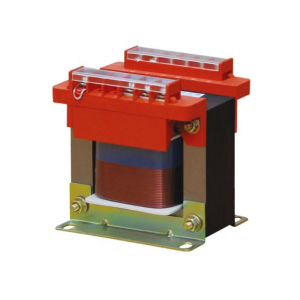

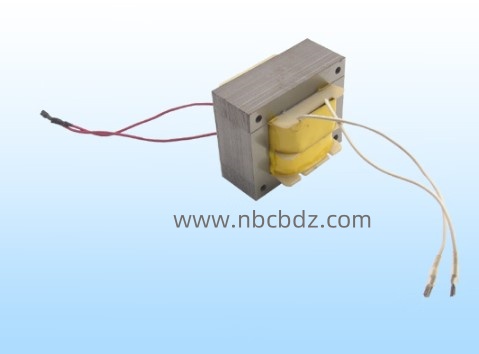

Low-frequency transformers continue to play an essential role in equipment that requires stable voltage regulation and predictable performance. Their presence is often understated, yet their contribution is fundamental to system continuity. Designers working with such components usually prioritize robustness, clear structure, and compatibility with long-term operational environments. These priorities influence how manufacturing processes are organized and refined.

One key factor in transformer production is the balance between tradition and adaptation. While core principles remain consistent, applications evolve alongside changes in infrastructure and usage scenarios. Manufacturers who respect established methods while allowing room for adjustment tend to offer solutions that integrate smoothly into both legacy systems and updated designs. This balance supports continuity without limiting future flexibility.

Communication between manufacturer and client is another defining element. Early-stage discussions about application context, installation conditions, and operational expectations help translate abstract requirements into tangible products. When this exchange is clear and ongoing, it reduces later adjustments and fosters a smoother transition from design intent to physical implementation.

Manufacturing environments that emphasize order often rely on well-defined workflows. From winding preparation to final assembly, each step is approached with attention to sequence and consistency. This structured flow supports repeatability and reduces unnecessary variation, which is particularly important for components expected to operate steadily over extended periods.

Documentation also plays a quiet yet meaningful role. Clear specifications, organized records, and accessible references help align internal teams and external partners. For engineers and maintenance personnel, such clarity simplifies evaluation and integration, allowing them to focus on system-level considerations rather than component uncertainty.

Sustainability considerations are increasingly part of production discussions. Rather than focusing on claims, many professionals emphasize practical actions such as material awareness and process efficiency. These measures contribute to responsible manufacturing while maintaining focus on functional requirements and realistic application needs.

From industrial equipment to infrastructure support, low-frequency transformers often serve as stable links within larger systems. Their reliability is shaped not only by materials and assembly, but also by the mindset behind their production. A measured approach that values consistency, dialogue, and incremental improvement can support long-term cooperation across diverse projects.

As power systems continue to evolve, the importance of grounded manufacturing principles remains unchanged. Observing how factories align process discipline with real-world application needs offers insight into the quieter side of technological progress.

If you are interested in seeing how such manufacturing perspectives are expressed through structure and practice, you may wish to step beyond this page and visit https://www.nbcbdz.com/ . The path there may reveal details that invite a closer look and a deeper understanding.